2025 Year-End Dinner Gala Recap: Celebrating Achievements, Honoring Excellence

2026-02-11

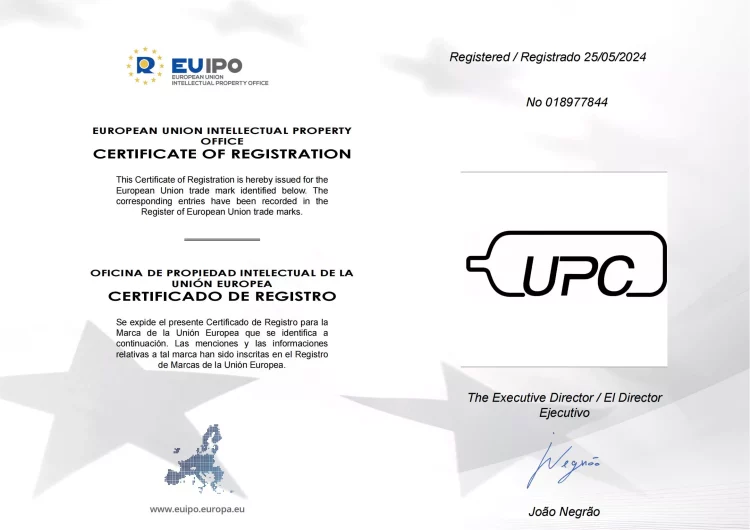

2025 Year-End Dinner Gala Recap: Celebrating Achievements, Honoring Excellence | UPC To mark the end of 2025 and celebrate the year’s hard-won achievements, UPC held its annual year-end dinner gala i…